Any hammer will do, right? Not necessarily. There are distinctive differences between basic woodworking and metalworking tools that you should take into consideration when filling your toolbox that we hope to cover here.

This post was inspired by a great YouTube video by Justin Voss. Check out the video below if you want to skip the reading.

Here are the subtle and significant differences between basic woodworking vs metalworking tools you should know when heading to your local hardware store.

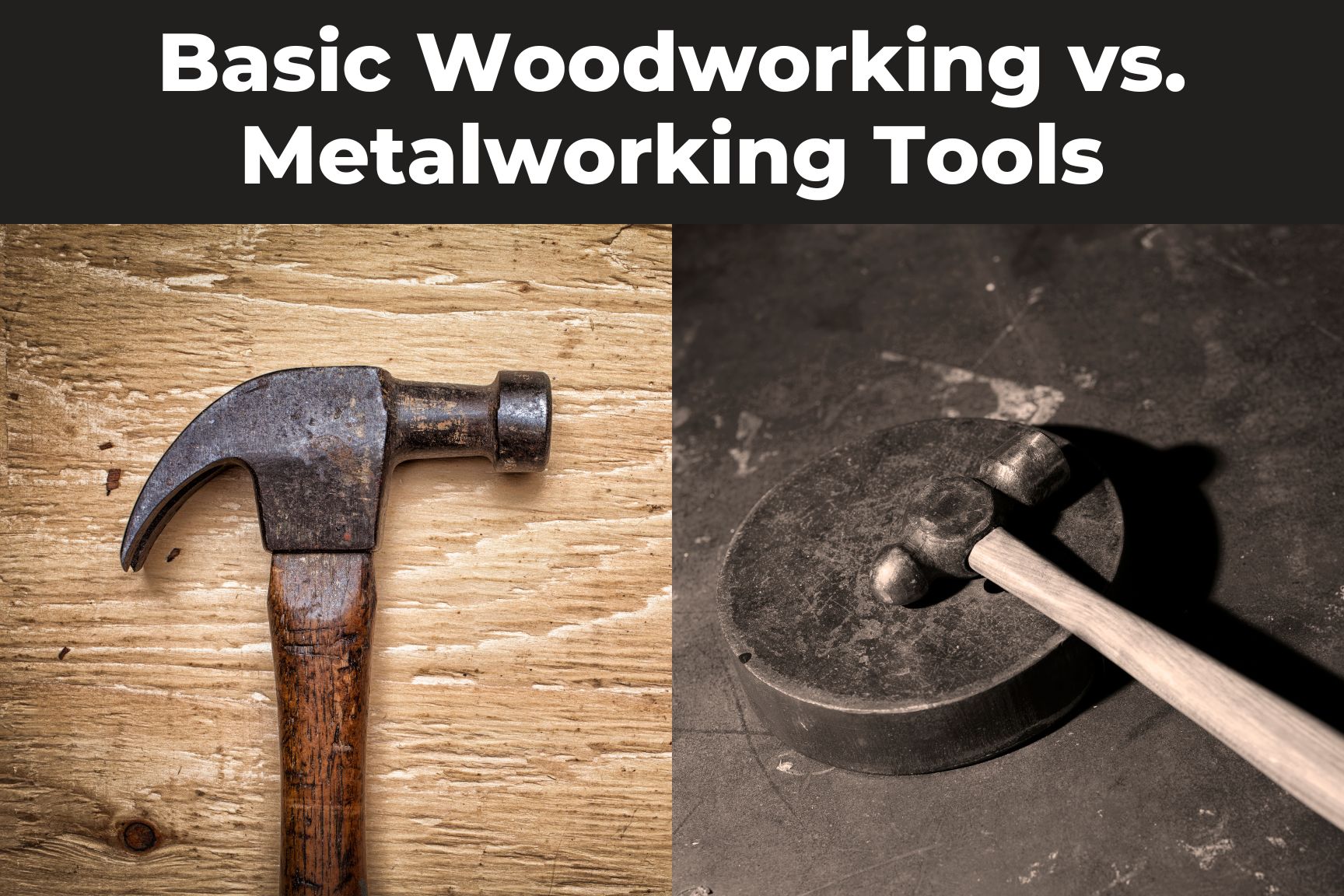

Hammers

Hammers…besides maybe a screwdriver, this is usually the first tool most people add to their collection.

Hammers for Woodworking

If you already own a single hammer, odds are it is the standard claw hammer. A claw hammer is one of the essential tools in any DIY-er or carpenter's toolkit. Whether hanging a picture frame or banging in nails, a claw hammer is a versatile tool that can make any task more manageable.

There are two claw hammers: the straight claw and the curved claw. The straight claw is better for general use, while the curved claw is better for pulling nails.

Hammers for Metalworking

On the metalworking side of things, the ball peen hammer will be a must for any novice metalworker to grab as one of your first metalworking tools. A ball peen hammer is a tool that mechanics and other tradespeople commonly use. It is also known as a machinist's hammer. The head of the hammer is usually made of steel and has a flat end used for striking punches or chisels and beating/bending metal, . The rounded (peen) side of the hammer has a point for surface hardening, rounding off edges of pins and rivets, or when you’re striking a small area and need a precision hit using the point of the peen.

A ball peen hammer can also drive nails like a claw hammer, but don't expect to be able to extract nails with it. Regardless, if you're going into metalworking, it is an essential tool.

The ball peen hammer is the must-have hammer for metalworkers, but there are additional specialty hammers that can be used for stretching, shrinking, and smoothing metal.

Clamps

When talking about clamps, you can use metalworking clamps on wood but it’s not ideal. Check out more information below.

Clamps for Woodworking

These days, woodworking clamps are primarily designed with plastic and large feet at the clamping portion. Regardless of the plastic material, these woodworking clamps can hold two pieces of wood together with enough force for wood glue to adhere properly or for nails to stay put.

Plastic clamps also allow for less marking on the wood itself. Metal clamps can leave marks on wood that can mess with the finish of your project.

Clamps for Metalworking

C-clamps (standard and vice grip) are mostly used for metalworking. Metalworking clamps can still work on woodworking projects, but the metal feet on the clamps can scratch or leave imprints on the wood. These clamps are made of metal and designed to withstand the heat of welding and other metalwork.

Metalworking clamps are also stronger to help hold two pieces of metal together with little movement.

Holesaws for Wood and Metal

To cut a perfect circle into an object, hole saws are usually the best choice. Hole saws for woodworking and metalworking are a bit different. We explain more in the following sections.

Hole Saws for Woodworking

A woodworker's hole saw can easily cut a perfect hole through any wood from softwoods to hardwoods. These hole saws are identifiable by the fact that they have larger teeth that can grip onto the wood and bite through it.

Bi-metal holesaws are made to work with both metal and wood, but there is a risk of generating more heat and burning the wood if used incorrectly.

Hole Saws for Metalworking

On the other hand, metalworking hole saws are designed for more precise cutting. In addition, these hole saws have smaller teeth (like you’d see on a hacksaw) that will not risk destroying your project as a woodworking hole saw. However, metalworking hole saws can also generate enough friction to smoke the area you're drilling into, so don't think you're smarter than the tool, and try to use the hole saw on a woodworking project.

Other options for drilling/cutting holes into metal include rotor broaches (Justin’s preference) and unibits/step bits (for sheet metal).

Cutting Wood and Metal

When it comes to cutting either material, the tool used is going to vary a lot. There are some metal cutting tools that can cut wood, but wood cutting tools won’t work with metal.

Saws for Woodworking

In a pinch, you can cut wood like a 2x4 with a regular old handsaw.

Outside of hand saws, the three main options of powersaws include a table saw, a skil saw, and a miter saw. Any of these saws can perform most woodworking cutting tasks. Each of these types of saws has a similar design using a circular blade with teeth to cut the wood. Any of these would be an investment you'll want to make if you plan to do any extensive woodworking in your near future.

Saws for Metalworking

For metalworking, chop saw blades would be the most similar metal cutting tools to wood cutting saws, with a chop saw using a large abrasive disc instead of a tooth-based cutting tool. However, a chop saw can create a lot of heat and sparks depending on the size of the metal you're cutting. On top of that, the saw blade itself gets smaller as you use it.

Horizontal band saws are another great option for precision cutting. These can be used to cut wood as well, but not as well as a circular saw. Vertical saws, on the other hand, are useful for cutting both wood and metal with the right blade.

Another option Justin didn’t mention would be cutting metal with an angle grinder. The above options are mostly set up to be used stationary in one place, whereas an angle grinder gives you the option to be portable and make quick, precise cuts. Cutting discs for angle grinders are great for making quick cuts for something like a metal bolt and can be used to cut larger objects like autobody parts and sheet metal.

Measuring Tools

Measuring wood and metal is a regular part of almost all woodworking or metalworking projects. Many people don’t realize that you’ll need different tools for each case.

Measuring Tools for Woodworking

One of the most basic tools in anyone’s toolbox (and often junk drawer) is a measuring tape. A quality measuring tape has easily readable tick marks and comes with standard carpenter markings like the distance between wall studs. In some cases you can also get by with a regular ruler.

Measuring Tools for Metalworking

Measuring metalworking is different from wood. Smaller measuring tapes with more precise tick marks will aid in any project. However, many metalworking projects require exact measurements, down to thousands of an inch, so dial or digital calipers are necessary.

Worktables

You’re going to need a place to work…

Worktables for Woodworking

The worktable in your dad's garage that he tossed together with a couple of sheets of plywood and a few 2x4s is almost a rite of passage for any novice woodworker. An extended worktable is critical to easily cut long pieces of wood with a miter saw or for enough surface area to work on larger projects.

Workbenches for Metalworking

Metalworking worktables, on the other hand, should at least have a metal surface. In addition, considering the sparks that saws can generate through cutting or welding, you need a workbench that does not risk catching on fire during regular use. An added bonus is that if you are welding, your part does not need to be directly clamped with a ground clamp since you can attach the ground clamp to the tabletop.

Drilling Holes

Drilling wood and drilling metal is quite different, so you’ll need appropriate drill bits.

Drill Bits for Woodworking

Any drill bit kit you can pick up from your favorite home center or hardware store will work well on woodworking projects. There are dozens of bits to choose from, but you definitely would not want to use wood drill bits for metal.

Drill Bits for Metalworking

On the metalworking side of drill bits, metalworking drill bits are generally tougher and require some drilling fluid to allow for clean holes. Tungsten carbide burrs are another great option for smaller holes.

Dust Collection

Dust collection is not just important for keeping your workplace clean, but also for keeping a safe environment for you to breathe in.

Dust Collection for Woodworking

Most of your saws these days come with a port that allows you to connect any shop vacuum. A clean shop is suitable for your respiratory system, so investing in a quality dust collection kit will prevent you from hacking up a lung after building something.

Dust Collection for Metalworking

Regular shop vacuums are not designed to work with the red hot sparks that metalworking creates. Metalworkers can use downdraft/grinding tables with a hood to help prevent sparks from flying across the room and collect small bits of metal that can become hazardous on the floor. Grinding tables can technically be used for woodworking, but is not recommended since it will collect flammable material that would ignite when you switch to metalworking with it.

Marking

Different materials will require different tools to make markings.

Marking for Woodworking

A pencil or a pen works is all you really need to mark your cuts on wood. You can also purchase a chalk line to create straight lines — no need to reinvent the wheel here.

Marking for Metalworking

Metalworking marking, however, needs something more like a marker, Sharpie, or a scribe so you can quickly locate the cutting line. Pencils and pens will either not leave a mark or it would be too light to see.