The discovery of techniques to forge metals and metal alloys was responsible for mankind to expand our civilization by leaps and bounds. Today, we do things a little differently than our pre-history metalworker ancestors, but the basics of making ferrous and non-ferrous metals are still the same.

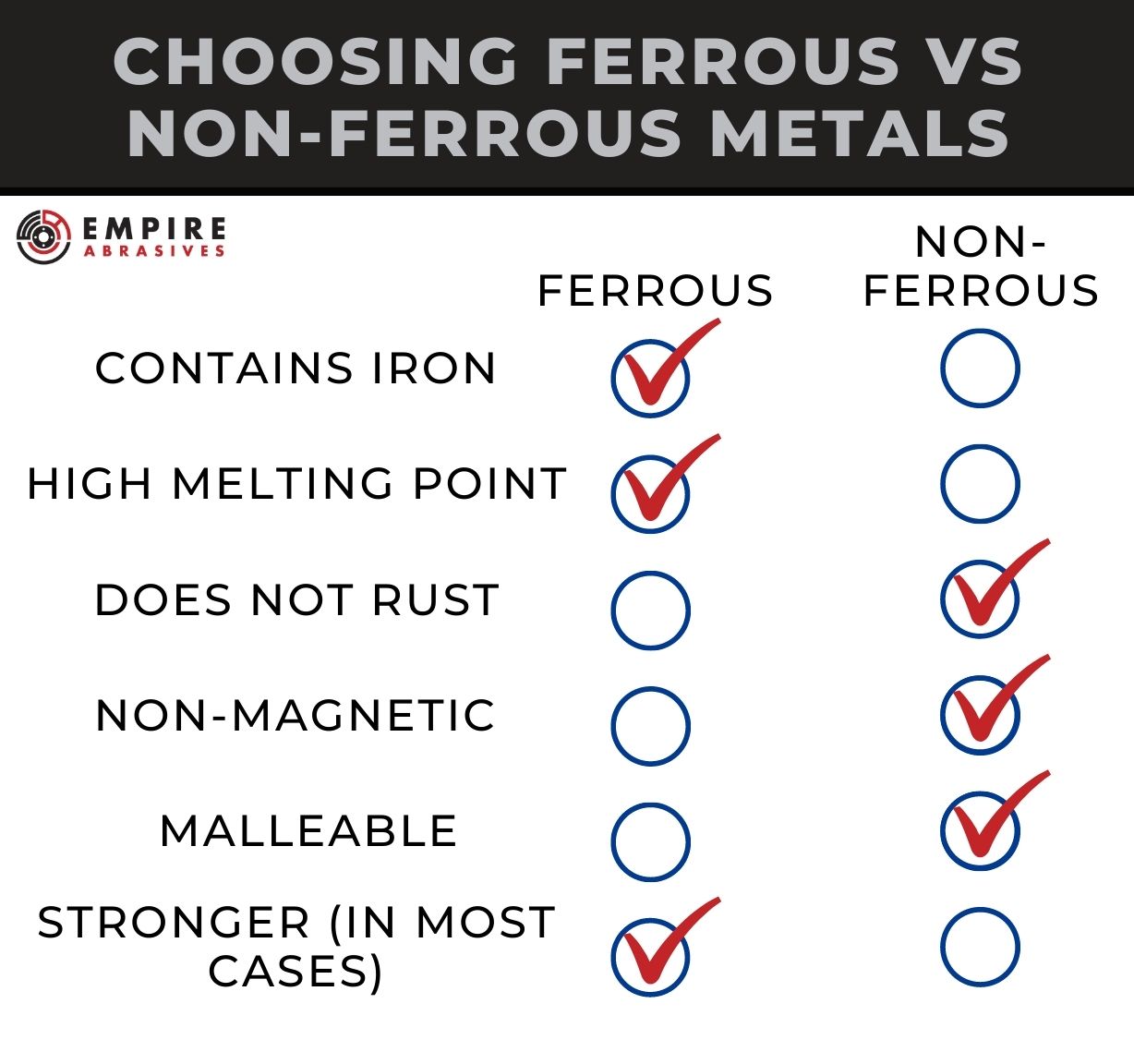

The fastest and easiest way to differentiate between Ferrous and Non-Ferrous metals would be whether the metal contains iron or not. The word “ferrous” literally means "containing or consisting of iron." So that means, ferrous metals will contain a certain percentage of iron. whereas non-ferrous metals don’t. The addition or exclusion of iron has significant effects on the metals. Both ferrous and non-ferrous metals have their own distinctive properties that also will dictate their usage.

History Lesson - Stone-Bronze-Iron Ages

Both bronze and copper are the most commonly recognized non-ferrous metals. Non-Ferrous metals have been used for substantially longer than ferrous. Dating back to around 5000BCE a technique was created to make bronze by smelting copper and alloying it with metals such as tin and arsenic. This marked the end of the Stone Age and transitioning into the Bronze Age.

Tin and copper had been the metals of choice because of their low melting point and ease to work with. Iron was naturally abundant, but it was not moldable on its own and it's melting point (1,650 °F) was higher than any kiln at the time could reach. Later around 1200BCE, man figured out how to create and mold iron for tools and weaponry, eventually leading mankind into the Iron Age.

As mankind progressed and learned more about metals and metallurgy, the use of ferrous and non-ferrous metals became more separated as their differences stood out starkly. Metalworkers discovered the pros and cons of each type of metal. Ferrous metals were valued for both their durability and their strength. Non-ferrous metals for malleability, containing non-magnetic properties, and resistance to both rust and corrosion.

All of this is important for when you are choosing a metal for your project. Do you need a metal that is durable and strong, or do you need a malleable metal that can withstand rust and corrosion? Does the metal need to be non-magnetic? Lightweight? Both? Each project is unique like the metals being used for them and should be chosen with careful consideration.

Ferrous Metal Properties and Common Types

Ferrous metals all contain a certain percentage of iron. Adding iron to a metal alloy significantly increases their tensile strength. Some of the most commonly used ferrous metals will be: cast iron, carbon steel, steel, and stainless steel. These metals are commonly used in industrial fabrication as well as architectural. You can also find these metals being used in engines and everyday appliances due to their magnetic properties. The higher carbon content of ferrous metals do make them prone to rusting. There are exceptions to this, however, with stainless steel.

While ferrous metals are predominantly used within the construction field, you can also find them with automobile manufacturing, piping, shipping container construction, and even in your own kitchen! They are, as previously mentioned, prone to rusting because of their carbon content. The best long term choices would be stainless steel or wrought iron. But, your cast iron dutch oven or pan is a prime example of ferrous metal use in everyday life.

There are quite a number of different types of ferrous metals. Another term for some of them would be structural steel. Structural steel consists of wrought iron, carbon steel, cast iron, alloy steel, and stainless steel. Since ferrous metals are known for their durability and amazing strength, this makes ferrous metal excellent for the construction of things such as apartment buildings, skyscrapers, vehicles, and railroad tracks.

When both carbon and iron are added together, you will find that the iron begins to harden. This is when steel is produced. Steel is extremely common within manufacturing, construction, and has many other industrial uses. The reason is that steel such a durable metal and incredibly strong, where many industries need that toughness that steel can provide.

The other common ferrous metal is iron, which comes in several variations. You’ll often find this in kitchens in its cast iron form. Cast iron is an alloy that derives from a combination of iron, silicon, and carbon. While cast-iron resists wear and tear fairly well, it is also hard and brittle. It is ideal for stoves, kitchenware, machining tools, and engines. Another commonly used iteration of iron is wrought iron. Wrought iron is different from cast iron due to less carbon content. It is most commonly used for stair railing, fencing, barbed wire, and chains. Wrought iron is also known for being resistant to both oxidation and corrosion.

While there are a significant amount of positives when it comes to ferrous metals, there are drawbacks to it as well. One of the most notable drawbacks to ferrous metal use is that they are usually inappropriate for wet or humid conditions as they are susceptible to rust and corrosion. However, as previously mentioned, wrought iron will be the exception to that rule along with stainless steel.

Examples of Ferrous Metals

- Steel

- Carbon Steel

- Stainless Steel

- Cast Iron/Wrought Iron

- Wrought Iron

- Pig Iron

Cutting and Grinding Ferrous Metals

Since this type of metal is so strong, you will need to choose abrasive products that are capable of taking on the task. Grinding wheels made of aluminum oxide or zirconia alumina can be used on most ferrous and non-ferrous metals, but are the best option for grinding iron and steel since they are tough enough to grind the metal without breaking down too fast. The same holds true for cutting ferrous metals.

Non-Ferrous Metal Properties and Common Types

As mentioned previously the distinctive lack of iron in non-ferrous metals is definitive difference between that and ferrous metals. The lack of iron has its own set of benefits such as their resistance to rust and corrosion, non-magnetic properties*, and malleability. *Non-magnetic can be a pro or a con depending what you are trying to accomplish.

The superior malleability of non-ferrous metals means they are much easier to mold, bend, and cut.. This is one of the reasons the discovery was so important to human’s advancement from the Stone Age to the Bronze Age.

Often non-ferrous metal is chosen because of its resistance to rust and corrosion making it ideal for things like airplanes and aerospace technology, traffic signs, gutters, and roofs. You will also find them where the appearance of the finished product is important such as musical instruments, fine jewelry, housewares, and décor. You will also occasionally find that some home appliances, like refrigerators, have ferrous metals in them for specifically for their magnetic capabilities.

Examples of Non-Ferrous Metals

- Aluminum

- Copper

- Copper alloys like bronze and brass

- Nickel, Palladium, Platinum

- Tin, Lead

- Zinc

- Titanium

- Precious metals like silver, gold, and platinum

Cutting and Grinding Non-Ferrous Metals

The increased malleability and lower melting point of non-ferrous metals is definitely a benefit for molding these metals, but definitely something to consider when cutting and grinding them. Using abrasives that build up too much heat can damage the metal. Additionally, using a cutting disc or grinding wheel that have already been used on a ferrous metal can cause contamination of the metal surface which can lead to rusting on an other-wise rust resistant surface.

The very low melting point of aluminum should be taken into consideration when cutting, grinding, or buffing this metal. It can easily be destroyed by using the wrong abrasives. Consider using a specific aluminum grinding wheel, aluminum cutting wheel, or calcium stearate coated aluminum flap disc made specifically to prevent damaging this heat-prone soft metal.

Non-ferrous metals also contain hazardous materials that when inhaled can cause severe health issues. When cutting or grinding non-ferrous metals, always work in a well ventilated area and wear the recommended safety equipment.

Ferrous and Non-Ferrous Metals: Is One Better Than the Other?

While there are distinctive differences between both ferrous and non-ferrous, their use will not just depend on the overall availability of the material, but the use of the fabricated product. Ferrous metals can be less expensive than their non-ferrous counterparts; there will be times on projects when the additional cost of non-ferrous metals will be necessary. In the end, they are both vital and necessary and one being better over another will all boil down to individual projects.