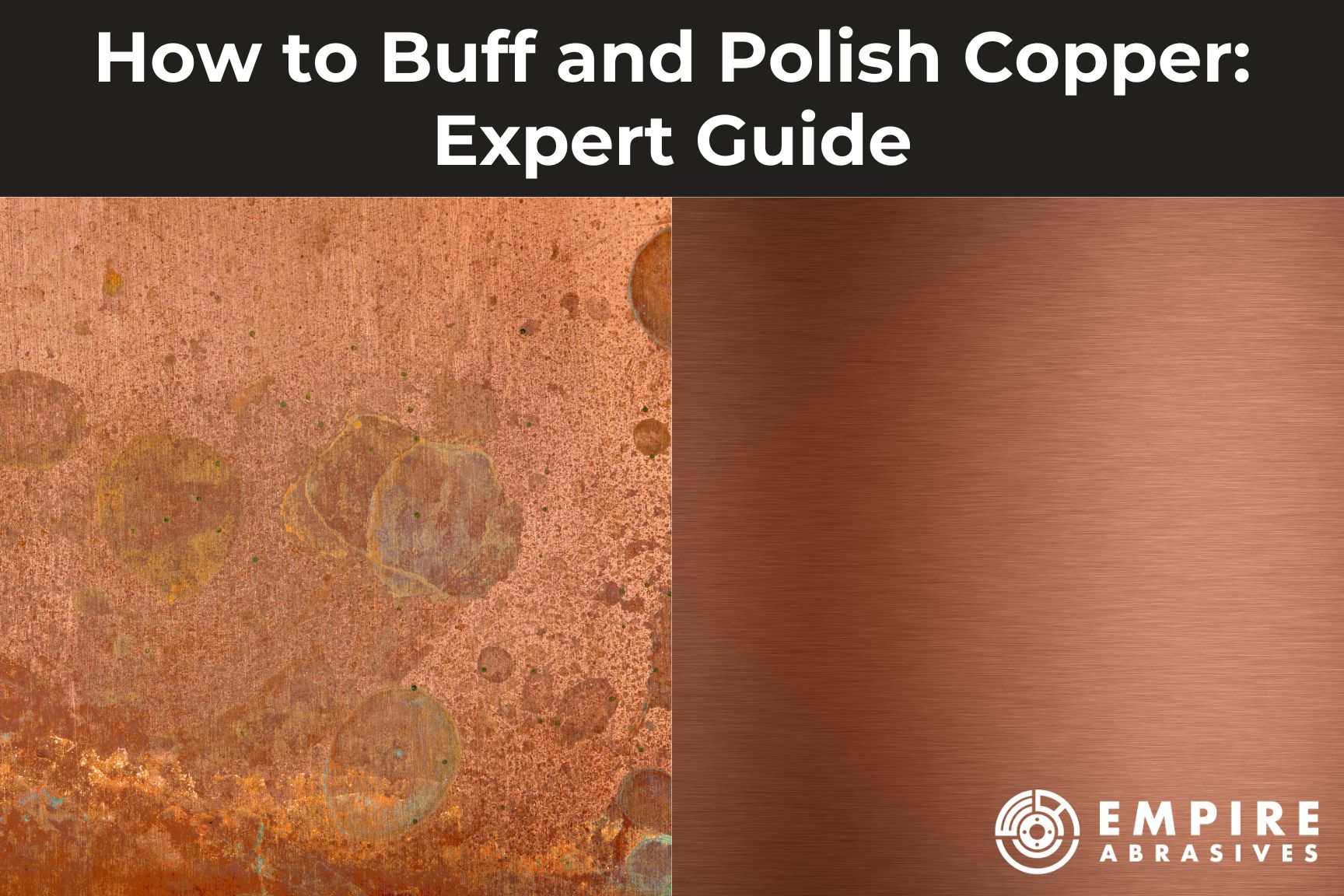

Copper is a beautiful and versatile metal, but over time it loses its luster, like any other metal. It can get scratched up or tarnished due to oxidation. Whether you're restoring antique copper cookware, polishing jewelry, or maintaining decorative copper fixtures, proper buffing and polishing techniques will keep your copper looking pristine.

In this guide, we’ll cover the step-by-step process of cleaning, buffing, and polishing copper to achieve a high-shine, mirror-like finish.

1. Understanding Copper’s Characteristics

Before you begin buffing and polishing, it's important to understand why copper tarnishes and how to determine if your item has a protective coating.

Why Copper Tarnishes:

Copper reacts with oxygen in the air and moisture, forming a layer of copper oxide that results in a dull or greenish patina. This natural process, called oxidation, is accelerated by exposure to humidity, salts, and acidic environments. Over time, oxidation can deepen into verdigris, a bluish-green layer commonly seen on aged copper surfaces, like the Statue of Liberty (which was originally shiny and reddish-brown).

Coated vs. Uncoated Copper:

Some copper items come with a protective lacquer or clear coat to prevent tarnishing. If your copper has a coating, it must be removed before buffing using acetone, lacquer remover, or fine-grit sandpaper. Testing for a coating can be done by lightly scratching an inconspicuous area. If no tarnish appears, the item likely has a protective layer.

Summary of the Buffing and Polishing Process

To fully buff and polish copper like a pro, follow these key steps (which we go into more detail about in the next few sections of this article):

-

Clean the Copper – Remove dirt, grease, and oxidation using natural or commercial cleaners.

-

Remove Heavy Tarnish – Use a specialized cleaner or fine-grit sandpaper or abrasive pads for deep oxidation removal.

-

Choose the Right Buffing Tools – Select appropriate buffing wheels and compounds for each stage.

-

Buff and Polish Using Power Tools – Follow a step-by-step process using machines for efficient polishing.

-

Hand Buffing Option – For those without power tools, achieve similar results with manual methods.

-

Protect and Maintain the Finish – Apply a protective coating and regularly clean to preserve the shine.

2. Preparing Copper for Buffing and Polishing

A. Cleaning the Copper

Before buffing, start by thoroughly cleaning the copper surface with warm soapy water and a soft cloth or sponge. You want to remove any dirt, grease, or oxidation. Soap and water usually works, but if you're having trouble with that, here are some other effective cleaning solutions:

-

Vinegar & Salt: Mix equal parts vinegar and salt to create a natural cleaning paste.

-

Lemon & Baking Soda: Cut a lemon in half, sprinkle baking soda on it, and rub it over the copper.

-

Commercial Copper Cleaners: Use for deep cleaning and faster results.

Tip: Rinse the copper thoroughly with clean water to remove any soap or cleaner residue. Pat it dry with a soft, lint-free cloth and make sure it is completely dry before moving onto further steps.

B. Removing Heavy Tarnish and Oxidation

Mild tarnish: For light tarnish, you can try using a mixture of lemon juice and salt. Apply the mixture to the tarnished areas, let it sit for a few minutes, and then gently rub it with a soft cloth. Rinse and dry thoroughly.

Heavy tarnish: For more severe tarnish, you might need to use a commercial copper cleaner or a chemical treatment like vinegar or diluted ammonia. Follow the instructions on the product label carefully and always test it in an inconspicuous area first.

C. Sanding (if necessary):

If your copper has significant tarnish, you may need to use fine-grit sandpaper (400-600 grit) or non-woven abrasive pads to remove oxidation. For intricate designs, use small abrasive brushes or a rotary tool with a fine sanding attachment.

Additionally, if it has scratches, dents, or other imperfections, you'll need to sand it before buffing and polishing.

Begin with a coarser grit sandpaper (e.g., 220-400 grit) to remove the imperfections. Work in one direction and maintain even pressure. Gradually move to finer grits of sandpaper (e.g., 600-800-1000 grit) to smooth out the surface and remove the scratches left by the coarser grit. If you're using a wet sandpaper, use water or mineral oil as a lubricant while sanding to prevent the sandpaper from clogging and to help create a smoother finish.

After sanding, thoroughly clean the copper surface again with warm soapy water to remove any sanding dust or debris. Rinse and dry completely.

3. Choosing the Right Buffing and Polishing Tools

You can buff and polish copper by hand, or you can use a power tool. This choice comes down to your personal preference.

A. Buffing Wheels

Different buffing wheels are used at various stages of the process:

-

Airway Buffing Wheels: Their construction allows for good airflow, which helps prevent overheating and extends the life of the wheel.

-

Spiral Sewn Buffing Wheels: These are a good choice for the initial cutting stage of buffing copper. The spiral stitching makes them more rigid than loose muslin wheels, allowing them to remove scratches and imperfections more effectively.

-

Loose Muslin Buffing Wheels: Loose muslin wheels are ideal for the polishing and finishing stages of buffing copper. The loose construction makes them softer and more flexible, allowing them to conform to the shape of the copper and produce a smooth, high-shine finish.

B. Buffing Compounds

Buffing compounds enhance the polishing process:

-

Gray Buffing Compound: For initial cutting and oxidation removal. Use with Spiral Sewn or other aggressive cutting wheels.

-

Brown Tripoli Buffing Compound: Enhancing the metal's color and further smoothing its texture. Use after Gray compound, with a slightly softer wheel like a firm cotton buffing wheel.

-

White Rouge Buffing Compound: Achieving a brilliant shine, while restoring a natural luster. Use after Tripoli, with a polishing wheel like a loose muslin wheel.

-

Green Rouge Buffing Compound (optional): If you're looking for a mirror-like finish. Use as the final step with a very soft finishing wheel, like a loose cotton or flannel wheel.

C. Hand vs. Machine Buffing

-

Hand Buffing: Use microfiber cloths or felt buffing pads for small projects, intricate details, or final touch-ups. Hand buffing is less effective for removing significant scratches or tarnish.

-

Machine Buffing: Use a polisher, bench grinder, rotary tool, or angle grinder with buffing wheels for larger projects, faster material removal, and a more consistent, professional finish.

4. Step-by-Step Process for Buffing and Polishing Copper with Power Tools

Step 1: Attach the Right Buffing Wheel

-

Use a spiral sewn wheel or yellow airway buff for the first buffing stage.

-

Switch to loose muslin wheels for final polishing. If using airway buffs, use a white untreated airway buffing wheel for intermediate stages and a flannel polishing wheel for final polishing.

Step 2: Apply Buffing Compound

-

Load the buffing wheel with gray compound for cutting.

-

Hold the spinning wheel against the compound stick to coat the fibers.

Step 3: Start Buffing

-

Hold the copper piece firmly and press it gently against the buffing wheel. Use a moderate speed with gentle pressure. Let the compound and the wheel do the work. Excessive pressure can generate heat and damage the copper. Keep the piece moving smoothly and evenly across the wheel's surface.

Step 4: Repeat with Finer Compounds

-

Switch to brown tripoli for intermediate polishing.

-

Finish with white rouge to achieve a brilliant shine.

-

Optional - go one step further with a green compound to see your reflection with a mirror-like finish.

Step 5: Final Cleaning and Protective Coating

-

Remove any compound residue with a clean microfiber cloth.

-

Apply a clear lacquer or wax coating to prevent future tarnishing.

Additional Tips:

Do not reuse a buffing wheel with different compound bars! The abrasives will stay embedded in the material, which will defeat the purpose of moving onto a finer bar.

Order a brass buffing and polishing kit to make finding the right products easier. This kit (link) is for aluminum but works just as well with copper.

5. How to Buff and Polish Copper by Hand

If you don’t have access to power tools, you can still achieve a beautiful shine on your copper using manual methods. Hand buffing takes more time and effort but can be just as effective.

Step 1: Choose the Right Polishing Cloth

-

Use a soft microfiber cloth or felt buffing pad to prevent scratches.

-

For deeper polishing, use cotton or muslin cloths.

Step 2: Apply Polishing Compound

-

Use gray buffing compound for heavy tarnish removal.

-

For intermediate polishing, apply brown Tripoli compound to the cloth.

-

Finish with white rouge to bring out a mirror-like shine.

Step 3: Start Buffing

-

Apply firm, circular motions across the copper surface.

-

Work in small sections to ensure even polishing.

-

Reapply the polishing compound as needed.

Step 4: Wipe and Protect

-

Use a clean cloth to wipe away excess compound.

-

Apply carnauba wax or clear lacquer to preserve the shine and prevent future tarnishing.

Tip: Regularly polish your copper by hand to maintain its luster and prevent heavy oxidation buildup.

6. Common Mistakes to Avoid

-

Skipping the cleaning step – Buffing over dirt or oxidation can scratch the surface.

-

Applying too much pressure – Can cause excess heat buildup and burn marks.

-

Using the wrong buffing compound – Always start with a cutting compound before moving to polishing.

-

Neglecting safety gear – Always wear safety glasses, gloves, and a mask.

7. Maintaining Polished Copper

-

Store copper in a dry, low-humidity environment.

-

Regularly clean with a soft cloth to remove fingerprints and dust.

-

Reapply a protective coating every few months.

Conclusion

Buffing and polishing copper doesn’t have to be difficult. By following the right steps—cleaning, choosing the appropriate buffing tools, applying compounds in stages, and finishing with a protective coat—you can keep your copper shining like new.

Ready to start your copper polishing project? Explore our selection of buffing wheels, polishing compounds, and abrasives at Empire Abrasives to achieve professional-quality results!