Ever found yourself in the middle of a sanding project and had a sanding disc that clogs up faster than it smooths? Or maybe you've had a perfectly smooth finish turn into a streaky mess thanks to too much heat buildup? If so, you're not alone. These are common challenges faced by woodworkers, autobody techs, and home DIYers. Well, we know something that can help - stearate coated abrasives.

What is Stearate Coating?

Stearate

coatings are a specialized treatment applied to specialty abrasive

products such as sandpaper, sanding discs, and grinding wheels. This treatment enhances the abrasives by reducing friction and heat buildup while also preventing clogging (loading) when sanding

or grinding.

Stearate

coatings are a specialized treatment applied to specialty abrasive

products such as sandpaper, sanding discs, and grinding wheels. This treatment enhances the abrasives by reducing friction and heat buildup while also preventing clogging (loading) when sanding

or grinding.

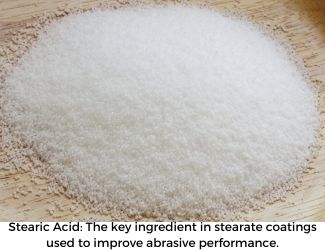

The stearate itself is a dry powder lubricant (seen in the image to the right). It consists of metallic salts derived from stearic acid, a fatty acid commonly found in animal and vegetable fats. Common types are calcium stearate, zinc stearate, aluminum stearate, and gold stearate.

Why Stearate Coatings are Used in Abrasives

Stearate coatings are used to enhance the performance and longevity of abrasive products. By reducing friction and preventing debris buildup, these coatings improve both the efficiency and durability of sanding discs, belts, and sandpaper sheets. This is particularly beneficial when working with soft or clog-prone materials like wood, coated surfaces, and autobody filler and heat sensitive materials like aluminum, plastic, and other non-ferrous metals.

How Stearate Coating Works in Abrasives

Stearate coatings

act as a lubricant on the surface of abrasives, reducing

excessive friction

between the abrasive grains and the material being worked on. Think of stearate

coating like a layer of microscopic ball bearings between the abrasive grains

and the material being worked on. It reduces friction, allowing the abrasive to

glide smoothly across the surface.

Stearate coatings

act as a lubricant on the surface of abrasives, reducing

excessive friction

between the abrasive grains and the material being worked on. Think of stearate

coating like a layer of microscopic ball bearings between the abrasive grains

and the material being worked on. It reduces friction, allowing the abrasive to

glide smoothly across the surface.

This reduction in friction means that less heat is generated during sanding or grinding, which helps to protect both the abrasive and the workpiece.

It also acts as a release agent, creating a “non-stick” surface on the abrasive. It prevents dust, debris, and removed material from sticking to and clogging the abrasive grains. This "non-stick" property is especially valuable when working with materials that tend to clog, like wood, paint, or plastic.

Isn’t Friction Needed for Grinding and Sanding?

Friction is necessary for grinding and sanding. It’s the friction between the abrasive grains and the workpiece that allows the material to be removed. However, what the stearate coating does is reduce the unwanted/excessive friction , which can lead to overheating, clogging (loading), and damage to both the abrasive and the workpiece.

Benefits and Advantages of Stearate Coatings

Stearate coatings offer a wide range of benefits that significantly improve the performance and user experience of abrasive products:

- Improved Cutting Efficiency: Reduced friction means less resistance, allowing the abrasive to cut faster and more smoothly. This leads to faster sanding and grinding operations.

- Reduced Loading and Clogging: Stearate coatings create a barrier that prevents debris from sticking to the surface, minimizing loading and clogging. This is especially beneficial when working with soft or gummy materials.

- Extended Product Life: Less friction and heat buildup reduce wear and tear on the abrasive, extending its lifespan. This means fewer abrasive changes and lower overall costs.

- Better Surface Finish: A smoother cutting action and less debris buildup result in a cleaner, more uniform finish.

- Cost-Effectiveness: While stearate-coated abrasives might have a slightly higher upfront cost, the improved performance and reduced downtime for switching out clogged abrasives can result in significant cost savings, especially with large-scale projects or frequent users.

- Protects Heat-Sensitive Materials: Reduced heat buildup can save heat-sensitive materials like plastics, composites, and certain metals from potential warping, melting, or discoloration.

Common Applications of Stearate-Coated Abrasives

Stearate-coated abrasives are highly versatile and offer numerous benefits across a wide range of industries and applications. Here are a few key areas where they excel:

Woodworking

Woodworkers often have issues with softwoods and coated surfaces that tend to clog up sandpaper quickly. Stearate-coated abrasives prevent the buildup of sawdust, resin, or finish. This benefits woodworkers with smoother, more efficient sanding as well as less need to swap out their abrasives as often.

Automotive Refinishing

In the automotive industry, stearate-coated abrasives are crucial for sanding down paint, primer, and fillers like Bondo. The coating helps prevent clogging and reduces the risk of surface imperfections like pigtails or scratches. The reduction in heat buildup also prevents burn-through on thin layers of paint or clear coats.

Metalworking

When working with metals, especially non-ferrous ones like aluminum, high friction and heat can cause a lot of problems. Stearate-coated abrasives help control heat buildup when polishing or grinding metals, preventing issues like warping, discoloration, or even changes in the metal's properties due to excessive heat. This makes them particularly valuable when working with softer metals like aluminum or brass.

Specific Tasks and Projects

- Sanding Paint, Varnish, or Clear Coats : Stearate-coated abrasives provide a smoother sanding experience when working with delicate, coated surfaces like paint or varnish. The anti-loading properties prevent streaking, scratching, or damaging the underlying surface while efficiently removing the top layer.

- Polishing or Grinding Metal: Whether you're working on metals or alloys, these abrasives minimize heat buildup, preventing the risk of warping or material damage during the grinding process.

- Smoothing Plastics or Composites : For those working with plastic or composite materials, stearate-coated abrasives keep the surface free from clogging, so you can continue sanding without damaging the material's integrity.

Stearate-Coated Abrasive Products at Empire Abrasives

At Empire Abrasives, we offer a variety of high-performance stearate-coated products designed to enhance your sanding and grinding projects. Below are some of our top products featuring stearate coatings, each designed to reduce loading, extend product life, and provide smoother finishes.

Calcium Stearate Coated Flap Disc for Aluminum

Brand:

BHA - Black Hawk Abrasives

Brand:

BHA - Black Hawk Abrasives

For those working with soft, non-ferrous metals like aluminum, copper, and nickel, the BHA Calcium Stearate Coated Flap Disc is an excellent choice. The disc is coated with a calcium stearate layer, which liquefies during use to create a protective barrier on the workpiece. This feature prevents loading (or "chip adhesion") and reduces heat buildup, ensuring both the disc and your workpiece remain cool and undamaged. With ceramic abrasive grains and a high-strength polyester backing , this flap disc is built for durability, making it ideal for grinding, blending, deburring, and edge chamfering .

Key Features :

- Ceramic abrasive grains with calcium stearate coating for no-load performance

- Suitable for all soft non-ferrous metals, especially aluminum

- High-strength polyester sanding flaps and reinforced fiberglass backing for extra durability

- Contaminant-free (contains less than 0.1% iron, sulfur, and chlorine)

6" PSA Gold Stearate DA Sanding Disc Rolls

Brand: BHA - Black Hawk Abrasives

Brand: BHA - Black Hawk Abrasives

If you’re working on surfaces prone to clogging, such as fiberglass, metals, and coated surfaces like paint or primer, the 6" PSA Gold Stearate DA Sanding Discs offer a solution. Coated with gold stearate, these sanding discs are perfect for reducing loading on surfaces such as fiberglass, metals, paint, primer, lacquers, and plastics. Available in a wide range of grits, from 60 to 600, these discs provide excellent finishing, stock removal, and long life, thanks to their heavy-duty D-weight backing for lower grits and C-weight backing for higher grits. The full resin bond and load-resistant stearate coating allow for fast cutting and an extended lifespan.

Key Features :

- Aluminum oxide grain with gold stearate coating for longer disc life and less clogging

- Available in a variety of grits for different applications

- Strong self-adhesive backing for easy application to orbital sanders

- Ideal for working on fiberglass, metal, wood, and drywall

Gold Stearate Longboard Rolls

Brand: BHA - Black Hawk Abrasives

Brand: BHA - Black Hawk Abrasives

This continuous sandpaper roll features a gold stearate coating and is designed for long-lasting performance on auto bodywork, woodworking, and general sanding applications . The stearate coating prevents clogging and reduces friction when sanding body filler, primer, or paint, resulting in smoother finishes. The heavy C-weight backing provides durability and tear resistance, while the PSA sticky back ensures a secure attachment to longboard sanders or straight-line air sanders.

Key Features :

- Aluminum oxide grains for rapid material removal

- Gold stearate coating for load resistance and smoother finishes

- Tear-resistant C-weight backing for added durability

- Full phenolic resin bond for superior grain adhesion

Green Film Longboard Continuous Sandpaper Roll

Brand: BHA - Black Hawk Abrasives

Brand: BHA - Black Hawk Abrasives

When you need flexibility and durability, the Green Film Longboard Sandpaper Roll delivers. Ideal for wet and dry sanding tasks, this roll features a tear-resistant polyester film backing that conforms to curves and contours, ensuring smooth, even sanding. The anti-clogging stearate coating keeps the sanding surface clean, reducing dust and extending the life of the abrasive. Perfect for ultra-fine finishing in automotive refinishing, woodworking, and metal polishing , this roll offers excellent results with minimal effort.

Key Features :

- Treated aluminum oxide grains for sharp, fast material removal

- Anti-clogging stearate coating for reduced dust and consistent results

- Tear-resistant polyester film backing for greater flexibility and durability

- Hook and loop backing for easy grit changes and secure attachment

- Water-resistant design for both wet and dry applications

Green Film PSA Wet / Dry Sanding Discs

Brand: BHA - Black Hawk Abrasives

Brand: BHA - Black Hawk Abrasives

For professionals working on a variety of surfaces, the Green Film PSA Wet/Dry Sanding Discs are perfect for achieving smooth, consistent finishes across a range of materials like wood, metal, and coated surfaces . With a water-resistant polyester backing and an anti-clogging stearate coating , these discs are built for durability and versatility in both wet and dry sanding applications. The treated aluminum oxide grains provide fast, precise cutting, while the pressure-sensitive adhesive (PSA) backing ensures easy attachment and removal for quick disc changes. Available in grits from 60 to 2000, these discs offer excellent value for a variety of sanding tasks

Key Features :

- Treated aluminum oxide grain for fast, smooth cutting

- Water-resistant polyester film backing for wet or dry sanding

- Anti-clogging stearate coating reduces dust and extends disc life

- Available in grit sizes ranging from 60 to 2000

Non-Loading Sandpaper Sheets

Brand: Mercer

Brand: Mercer

These 9 x 11 non-loading sandpaper sheets from Mercer feature silicon carbide grains and a special zinc stearate coating designed to prevent loading during dry sanding. With these non-loading and low heat generating characteristics, the sandpaper remains effective for longer, even on tough surfaces like lacquer, paint, body fillers, metal, and plastic . These sandpaper sheets are ideal for tasks that require consistent sanding without frequent changes due to clogging, making them a perfect choice for stripping paint or dry sanding tasks.

Key Features :

- Silicon carbide grain for sharp, fast cuts

- Zinc stearate lubricant for anti-clogging and heat resistance

- High-quality latex-backed paper for durability and flexibility

Conclusion

Stearate-coated abrasives offer numerous advantages that can significantly improve your sanding, grinding, and finishing tasks. Whether you're a professional woodworker, an automotive technician, or a DIYer, using stearate-coated abrasives can give you a cleaner finish, extended product life, and better overall performance.

To explore our range of stearate-coated abrasives, check out our sanding discs, sanding belts, and PSA discs at Empire Abrasives. Our products are designed to meet the demands of your toughest projects, helping you achieve professional results every time.

Don’t let clogged abrasives slow you down. Upgrade to Empire Abrasives' stearate-coated products today and get a cleaner, smoother finish every time.