TPI, in terms of saw blades, stands for Teeth Per Inch on the blade. It’s an important number to consider when shopping for any kind of metal saw blade for cutting metal, wood, or any other material. Different TPIs blades can cut different materials and provide different end results. In this article, we’ll discuss what a TPI blade number is and how you can use that to pick the right blades.

Understanding TPI

TPI is used for all sorts of blades used on power tools (ex. band saw blades and reciprocating saw blades) and handheld saws (ex. Hand saws and hacksaw blades). It is literally measured by how many teeth fit within an inch of the blade’s surface. For example, if you count the teeth on one inch of a 14 TPI blade, it will have 14 teeth in it. Higher TPI means there are more teeth and a lower TPI means there are less teeth.

What are the Different TPI Numbers?

A. Low TPI Blades (e.g., 6-18 TPI):

Best for rough, fast cuts and thicker materials

Low TPI blades have fewer teeth per inch, which makes them ideal for rough, fast cuts. The larger teeth remove more material with each pass, reducing the risk of clogging and allowing for quicker cutting. This makes them the best choice when you’re cutting through thicker materials. When working with thick wood, plastic, or metal, a blade with a low TPI will make the job faster and easier. However, the cut surface will be rougher and may require additional finishing.

B. Medium TPI Blades (e.g., 18-24 TPI):

Best for general purpose use

Medium TPI blades give you a balance between speed and finish quality, making them a great choice for general-purpose use. Blades with a TPI between 18 and 24 are versatile and can handle a variety of materials, thick and thin. Whether you're cutting through metal pipes, wooden boards, or plastic sheets, a medium TPI blade offers good control and a relatively clean cut without sacrificing too much cutting speed. This makes them a great choice for everyday tasks.

C. High TPI Blades (e.g., 24+ TPI):

Best for smooth, fine cuts and thinner materials

High TPI blades have a greater number of teeth per inch, which will give you finer, smoother cuts. The increased tooth count means each tooth removes less material per pass, which reduces the likelihood of splintering or chipping. The trade off of high TPI blades is that they cut more slowly compared to lower TPI blades. They are best when cutting thinner materials and/or where precision and clean edges are important for you. For instance, if you're working with sheet metal, thin wood panels, or delicate plastic, a high TPI blade will provide the clean, smooth finish you’re looking for.

How TPI Affects Saw Blade Performance

Cutting Speed:

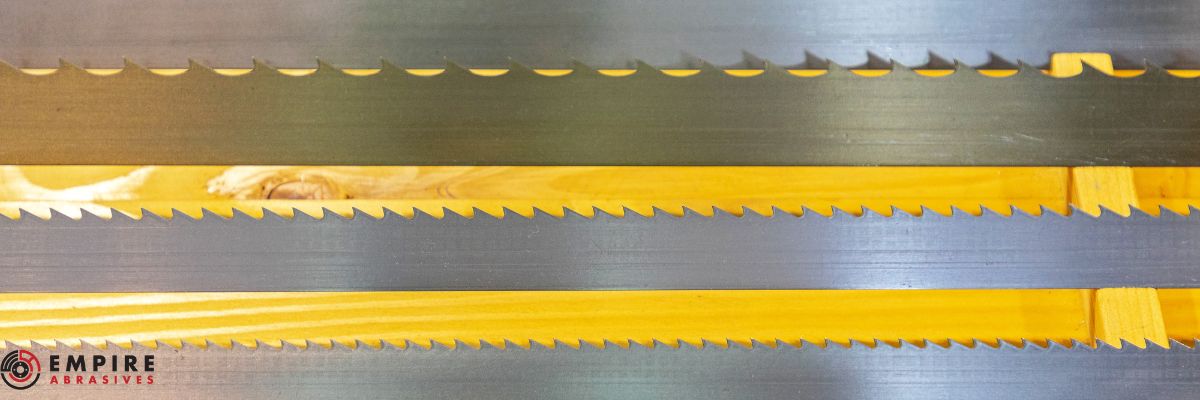

TPI significantly affects the cutting speed of any saw blade. Blades with lower TPI have fewer teeth and more space between each, which takes larger bites out of the material. This results in faster cutting, making them ideal for rough cuts and situations where speed is a priority. On the other hand, high TPI blades have more teeth that are closer together, which removes less material with each pass.

Cut Quality:

TPI also has a direct effect on the quality of a cut. Higher TPI blades result in much smoother cuts due to the increased number of teeth with smaller gaps between them. Each tooth takes off a smaller amount of material, resulting in less splintering, chipping, and overall smoother edges. Low TPI blades, with their cutting teeth spaced out more, produce rougher cuts due to the more aggressive material removal.

Material Considerations:

The type of material being cut needs to be considered when choosing which TPI you need in your blade. Different materials require different TPI ranges to get the best cutting speed and finish quality.

Wood:

- Softwoods (Pine, Cedar): 10-18 TPI is generally recommended for softwoods. A lower TPI (10-14) can be used for ripping (cutting with the grain), and a slightly higher TPI (15-18) would be better for crosscutting (cutting against the grain).

- Recommended Blade Types: Circular saw blades, table saw blades, hand saws

- Hardwoods (Oak, Maple, Walnut): Use 18-24 TPI blades for hardwoods. A medium TPI (18-20) works well for general cutting, while a higher TPI (22-24) is preferred for finer cuts and intricate work.

- Recommended Blade Types: Circular saw blades, table saw blades, miter saw blades

- Plywood & Veneers: 24-30 TPI is typically used for plywood and veneers. The higher tooth count helps prevent splintering and chipping of the thin layers.

- Recommended Blade Types: Circular saw blades, table saw blades, jigsaw blades

Metal:

- Non-Ferrous Metals (Aluminum, Copper, Brass): 32-64 TPI is recommended for softer, non-ferrous metals. Higher TPI blades produce cleaner cuts with less burring.

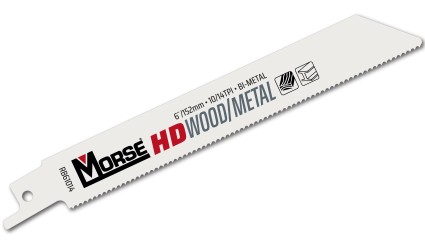

- Recommended Blade Types: Hacksaw blades, reciprocating saw blades, band saw blades

- Ferrous Metals (Steel, Iron): 14-32 TPI blades are suitable for harder, ferrous metals. A lower TPI (14-18) is good for thicker materials, while a higher TPI (24-32) is better for thinner sheets and smoother cuts.

- Recommended Blade Types: Hacksaw blades, reciprocating saw blades, band saw blades

Plastic:

- Acrylic: 32-64 TPI is recommended for acrylic sheets. Higher TPI blades help prevent chipping and cracking.

- Recommended Blade Types: Circular saw blades, table saw blades, jigsaw blades

- PVC: 10-14 TPI is suitable for PVC pipes and fittings. Lower TPI blades are better for cutting thicker PVC materials.

- Recommended Blade Types: Hand saws, circular saw blades, reciprocating saw blades

- Polycarbonate: 18-24 TPI is ideal for polycarbonate sheets. A medium TPI provides a good balance between cutting speed and finish quality.

- Recommended Blade Types: Circular saw blades, table saw blades, jigsaw blades

The above are general guidelines, and the ideal TPI and cutting tool can vary depending on the specific material thickness and desired finish. Remember, the goal is to balance cutting speed and cut quality based on your project requirements. If you have any questions or need assistance, our team is here to help.

Additional Considerations When Choosing a Blade

TPI isn’t the only factor that goes into choosing the right blade for your project. There are other considerations and product specifications to consider:

Tooth Pitch:

Tooth pitch is the distance between the tips of adjacent teeth. It's often related to TPI, but not always directly. Some blades have variable tooth pitch, where the distance between teeth varies along the blade's length. This design helps reduce vibration and noise while improving cutting efficiency.

Blade Material:

The material of the saw blade itself plays a role in its durability and cutting performance. Common blade materials include:

- High-Speed Steel (HSS): Versatile and affordable, suitable for most general cutting applications.

- Carbide-Tipped: More durable and heat-resistant than HSS, ideal for cutting harder materials like metal and hardwoods.

- Bi-Metal: Combines flexibility with durability for cutting metal and wood with a longer lifespan than standard steel blades.

- Diamond-Tipped: Extremely hard and wear-resistant, perfect for cutting abrasive materials like tile, stone, and concrete.

Choose a blade material that matches the material you'll be cutting and the frequency of use.

Tooth Shape:

The shape of the teeth on a saw blade influences its cutting action and the finish. Common tooth shapes include:

- Flat Top (FT): Teeth are flat on top. Used for ripping wood, with fast and aggressive cuts.

- Alternate Top Bevel (ATB): Each tooth is beveled in opposite directions for both ripping and crosscutting..

- Triple Chip Grind (TCG): Ideal for cutting non-ferrous metals and plastics, producing clean cuts with minimal burring.

Select a tooth shape that matches the type of cut you need to make and the desired finish.

FAQ

Q: What does TPI stand for and why is it important?

A: TPI stands for Teeth Per Inch; the number of teeth on a saw blade per inch of its length. It's important because it affects the cutting speed, quality, and its ability to cut different materials. Higher TPI blades produce smoother cuts but cut slower; lower TPI blades cut faster but leave rougher edges.

Q: Is a higher TPI a better saw blade?

A: It depends on what you need it for. A higher TPI generally results in smoother cuts, but it also means slower cutting speed. The ideal TPI depends on the material being cut, the desired cut quality, and the type of saw blade being used.

Q: How often should you replace your saw blade?

A: Replace your saw blade when you notice signs of dullness, such as increased effort to cut, burning or tear-out of the material, or visible damage to the teeth. Regular maintenance and proper blade selection can extend blade life.

Q: What happens if you use the wrong TPI blade?

A: Using the wrong TPI blade can result in poor cutting performance, rough or splintered cuts, blade binding, and even potential damage to the material or saw. Always choose the appropriate TPI for the material you are cutting.