Drywall finishing is the process of preparing drywall panels for painting, texturing, or other decorative treatments. It involves several steps, one of which is sanding. Sanding drywall creates a smooth and even foundation that prepares the surface for tasks such as painting or wallpapering.

Drywall finishing is the process of preparing drywall panels for painting, texturing, or other decorative treatments. It involves several steps, one of which is sanding. Sanding drywall creates a smooth and even foundation that prepares the surface for tasks such as painting or wallpapering.

Using the right sandpaper grit for drywall can make or break your work when you want to achieve a smooth, professional looking finish. Choosing the wrong grit(s) can result in scratches, uneven surfaces, or even damage to the drywall. This article will help you understand which grit to use at each stage to get the best results.

Sanding Process for Drywall Finishing

Drywall finishing involves multiple stages of sanding and re-applying compound. The goal is to get a smooth and even surface that paint can adhere to and shows no signs of imperfections once finished.

This is a simplified explanation of the steps you'd take when sanding drywall.

- Initial Sanding: After the joint compound has dried completely, you’ll sand down major imperfections, ridges, and tool marks. This step can involve reapplying joint compound and several stages of sanding.

- Detail Sanding: At this point, you can use a hand sander or sanding sponge for spot sanding and to clean up corners, edges, and areas around outlets.

- Final Sanding: After addressing major imperfections, a fine-grit sandpaper is used on the entire surface.

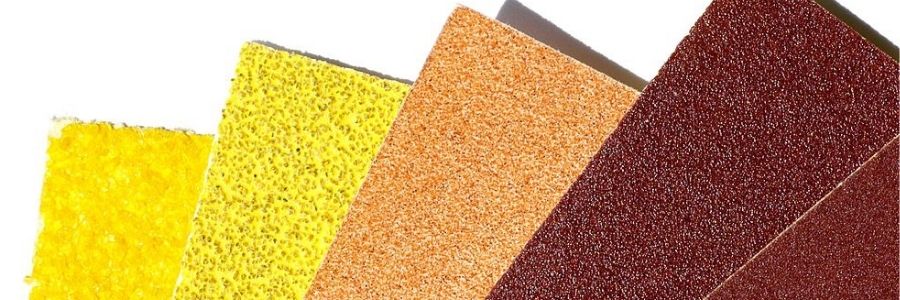

Different Grit Levels Explained

Sandpaper grit refers to the size of the abrasive grains on the sandpaper sheets. Higher numbers mean more grains per inch, and a finer sandpaper. Lower numbers mean less grains per inch, and a coarser grit. Here's a breakdown the grits you’ll likely use when sanding drywall:

Semi-Coarse Grits (80-100): For Heavy Duty Sanding

Coarse grits are used for heavy sanding tasks like removing thick layers of joint compound and leveling uneven surfaces. If you applied a thicker coat of joint compound, you might start with a coarser grit (80-100 grit) to remove excess material before moving on to finer grits. For minor imperfections or a fairly even surface, you may be able to skip this grit.

Medium grits (120-150): Smoothing the Surface

Medium grits are used for general sanding and to smooth out the surface after the initial sanding step. This grit range refines the surface and prepares it for the final sanding stages.

Fine grits (180-220): Finishing Touches

Fine grits are used for the finishing touches to make sure the drywall surface is smooth and free of minor imperfections. These grits are usually used just before painting or applying wallpaper.

Extra-fine grits (220+): Extra Smoothing

Extra-fine grits are used when you want an ultra-smooth finish before painting. It helps when you plan to use high gloss paint that will highlight the smallest imperfections. For most drywall sanding, it isn’t always going to be needed.

Choosing the Right Grit for Each Stage (Manual Sanding)

Now that you understand the different grit levels, let's explore which grits are best suited for each stage of the drywall sanding process. Here's a detailed guide on choosing the right grit for different stages when sanding by hand, with a sanding block, or a sanding pole:

Now that you understand the different grit levels, let's explore which grits are best suited for each stage of the drywall sanding process. Here's a detailed guide on choosing the right grit for different stages when sanding by hand, with a sanding block, or a sanding pole:

Initial Sanding: Removing Large Imperfections

Use semi-coarse grits (80-100) to get rid of large bumps and level out any uneven areas. This step can usually be skipped if the joint compound is feathered well, and the surface is relatively even.

Intermediate Sanding: Smoothing Out Surfaces

This step is often the actual initial sanding step, unless a coarse grit was needed, as mentioned in the previous step. Medium grits (usually 120 followed by 150) are used here to refine the surface. This step smooths out any remaining imperfections and prepares the drywall for the final sanding.

Final Sanding: Preparing for Paint or Finish

Use fine grits (180-220) to get the surface perfectly smooth and ready for paint or finish. This stage is critical for achieving a perfect finish.

OPTIONAL: Extra Smooth Finish

Some professionals will use even finer grits (320 or 400) for a super smooth finish. This is usually done if they plan to use high-gloss paint that will show even the smallest imperfections. This step might be unnecessary for most applications as it can be time-consuming and risks over-sanding.

Choosing the Right Grit for Each Stage (Power Sanding)

Power sanders are a great way to speed up the sanding process, but they can also be more aggressive than hand sanding. Here's how to choose the right grit for power sanding drywall:

Power sanders are a great way to speed up the sanding process, but they can also be more aggressive than hand sanding. Here's how to choose the right grit for power sanding drywall:

- Initial Sanding: Start with a finer grit than you would for hand sanding, such as 120 grit. This will help prevent gouging or damaging the drywall surface.

- Intermediate Sanding: Move to a slightly finer grit, like 150 grit, to further smooth the surface and remove any scratches left by the initial sanding.

- Final Sanding: Finish with a very fine grit, such as 180 or 220 grit, to achieve a smooth, even surface that is ready for paint or primer.

Power Sanding Tips:

- Light Pressure: Use light pressure and keep the sander moving to avoid creating divots or uneven spots. Let the tool do the work for you.

- Check Frequently: Regularly inspect your work to make sure you aren’t over-sanding and damaging the drywall.

- Dust Collection: Consider using a power sander with a built-in dust collection system or attach a shop vac to minimize dust and debris.

Recommended Drywall Sanding Products

These versatile rolls offer 150 feet (50 yards) of premium cloth-backed sandpaper, perfect for various drywall sanding tasks. The cloth backing ensures durability and flexibility, allowing for easy handling and long-lasting performance. Available in widths of 1 inch, 1-1/2 inch, and 2 inches, these rolls can be cut to any desired length to cater to different project needs, from tight corners to larger surface areas. The aluminum oxide abrasive provides excellent cutting power and longevity, making it ideal for smoothing drywall joints and removing excess compound. Note - these sandpaper rolls are only used when sanding by hand.

Gold Longboard Sandpaper Rolls

Available in both PSA (Pressure Sensitive Adhesive) and hook and loop options, these rolls are designed for use with longboard sanders, enabling efficient sanding of large drywall surfaces. The gold stearate coating features anti-loading properties, preventing clogging and ensuring consistent performance throughout the sanding process. The premium aluminum oxide abrasive delivers a superior finish while maintaining durability. These rolls are particularly useful for achieving smooth walls and ceilings in larger rooms or hallways.

Empire Abrasives offers a wide range of hook and loop sanding discs, available in sizes from 2 inches to 7 inches. These discs feature high-quality aluminum oxide grain for efficient material removal and a long-lasting cut. They come with a load-resistant coating to prevent clogging, ensuring smooth sanding throughout the job. The hook and loop backing allows for quick disc changes, improving productivity. These discs are ideal for both initial rough sanding and finer finishing tasks on drywall.

5" 5 Vac Hole Premium Gold Hook & Loop Discs - Velcro Type

5" 5 Vac Hole Premium Gold Hook & Loop Discs - Velcro Type

These sanding discs feature a premium aluminum oxide grain for effective material removal and a load-resistant gold stearate coating to prevent clogging. The 5 vacuum holes enhance dust extraction, improving visibility and reducing cleanup time. The hook and loop backing allows for quick and easy disc changes on compatible power sander tools, increasing productivity during drywall sanding projects.

5" Premium Film Hook & Loop Wet or Dry Sanding Discs

5" Premium Film Hook & Loop Wet or Dry Sanding Discs

The tear-resistant polyester film backing significantly reduces dust and prevents deep scratch marks, resulting in a smoother finish. The premium treated aluminum oxide grain ensures durability and produces an even finish without swirl marks. These discs are particularly useful for final sanding stages and achieving a professional-quality surface on drywall.

Peel & Stick Discs | PSA Sanding Discs

PSA sanding discs are available in sizes ranging from 5 inches to 12 inches, providing options for different drywall sanding requirements. These discs are easy to apply and remove, ensuring quick and efficient sanding. The strong adhesive backing ensures they stay securely in place during use.

6" PSA Gold Self Adhesive DA Sanding Disc Rolls Multi Pack

6" PSA Gold Self Adhesive DA Sanding Disc Rolls Multi Pack

These self-adhesive discs feature an aluminum oxide grain for efficient material removal and a load-resistant gold stearate coating to prevent clogging. The easy rip and peel roll design allows for quick disc changes, enhancing productivity. These discs are excellent for use with dual-action sanders, providing a balance of speed and control when sanding larger drywall areas or preparing surfaces for painting.

Our 9" x 11" aluminum oxide sandpaper sheets are versatile and can be used for hand sanding or with sanding blocks. They are available in various grit sizes to suit different drywall sanding stages, from rough sanding to fine finishing. The high-quality aluminum oxide abrasive ensures a consistent cut and long-lasting performance, making these sheets an essential tool for any drywall sanding project. Also available in emery cloth, non-loading, and wet-dry silicon carbide.

Additional Considerations

All of the recommendations above are for general drywall sanding and will work great for most DIY projects. The recommendations could vary slightly based on several factors.

- Personal Preference: Some professionals may have their preferred grit combinations based on experience and the specific project.

- Joint Compound Type: Different brands and types of joint compound may require slight variations in grit selection.

- Desired Finish: If you want a super smooth finish for a high-gloss paint, you might use finer grits overall.

If you want personalized advice, contact our Abrasives Experts who would be happy to answer your questions.

Pro Tips for a Smooth Finish

Achieving a smooth finish on drywall requires not only the right grit sandpaper but also the right tools and techniques. Here are some quick drywall sanding tips to help you get the best results:

Techniques for Even Sanding

- Circular motions: Sand in circular motions to avoid creating grooves or lines on the drywall. This technique helps distribute the sanding pressure evenly.

- Consistent pressure: Apply consistent pressure to avoid gouging the drywall. Let the sandpaper do the work instead of pressing too hard.

- Start from the top: Begin sanding from the top of the wall and work your way down. This method helps you catch any dust or particles falling from higher sections.

Use Sanding Blocks and Poles

- Sanding blocks: Sanding blocks are essential for maintaining a flat sanding surface and preventing hand fatigue. They help distribute pressure evenly for a smoother finish.

- Sanding poles: Sanding poles allow you to reach areas without the need for ladders. They also help maintain even pressure across the surface. Consider using a sanding pole when working on ceilings or high walls.

Avoiding Common Mistakes

- Over-sanding: Over-sanding can damage the drywall and create uneven surfaces. Check your progress frequently to avoid sanding too much.

- Wrong Grit Usage: Using the wrong grit for the job can lead to poor results. Using too coarse a grit can leave scratches and marks that are difficult to cover with paint. Too fine a grit for initial sanding can make it challenging to remove larger imperfections and may prolong the sanding process. Refer to the previous sections to choose the right grit for each stage.

- Not Cleaning Between Grits: Clean the surface between sanding stages to remove dust and debris. Dust and debris left on the surface can cause scratches when you move to a finer grit. Paint or primer also may not adhere properly to a dusty surface. Use a damp cloth or vacuum to clean the surface thoroughly.

Conclusion

Your satisfaction is our priority. That's why Empire Abrasives offers a wide range of drywall sanding solutions to fit every project and skill level. We're confident that you'll find the perfect products to help you achieve your best results. Start browsing today and experience the difference.